Originating from Japanese manufacturing, Poka Yoke is a powerful design principle aimed at reducing human errors and enhancing quality across various industries. This blog post will explore ten Poka Yoke examples in real life, showcasing how these clever solutions effectively prevent errors, enhance safety, and boost productivity in our daily lives.

What is Poka Yoke?

Poka Yoke is a Japanese term that translates to “mistake-proofing” or “error-proofing”. It represents a key concept in quality management and process improvement.

Originating from the manufacturing industry, Poka Yoke aims to prevent mistakes before they occur by designing processes that inherently minimize the chance of human error. In essence, this approach emphasizes simplicity and intuitiveness. As a result, this ensures that systems or products are designed in such a way that incorrect actions become impossible or immediately apparent. Through the implementation of Poka Yoke techniques, organizations can enhance the reliability and quality of their operations, reduce defects, and improve overall efficiency.

Beyond industrial applications, Poka Yoke principles can be adapted to everyday life. In fact, it offers practical solutions that enhance efficiency and safety. By integrating these thoughtful design elements into daily routines, individuals can reduce the likelihood of mistakes, streamline tasks. Ultimately, fostering a more organized and productive environment.

History of Poka Yoke

Poka Yoke was originally developed in the 1960s by Shigeo Shingo, an industrial engineering engineer at Toyota. As part of the Toyota Production System (TPS), Shingo introduced Poka Yoke with the primary goal of eliminating defects by designing processes that make it impossible to make mistakes. This innovative approach was a response to the challenges of maintaining high-quality standards in mass production environments, where even minor errors could lead to significant inefficiencies.

By integrating mistake-proofing systems into the manufacturing processes, Shingo’s Poka Yoke systematically reduced the likelihood of human error. Thus, enhancing the reliability and quality of Toyota’s operations. This method contributed to the success of the Toyota Production System and laid the groundwork for modern quality management practices. Consequently, it has established itself as a fundamental aspect of Lean manufacturing principles across the world.

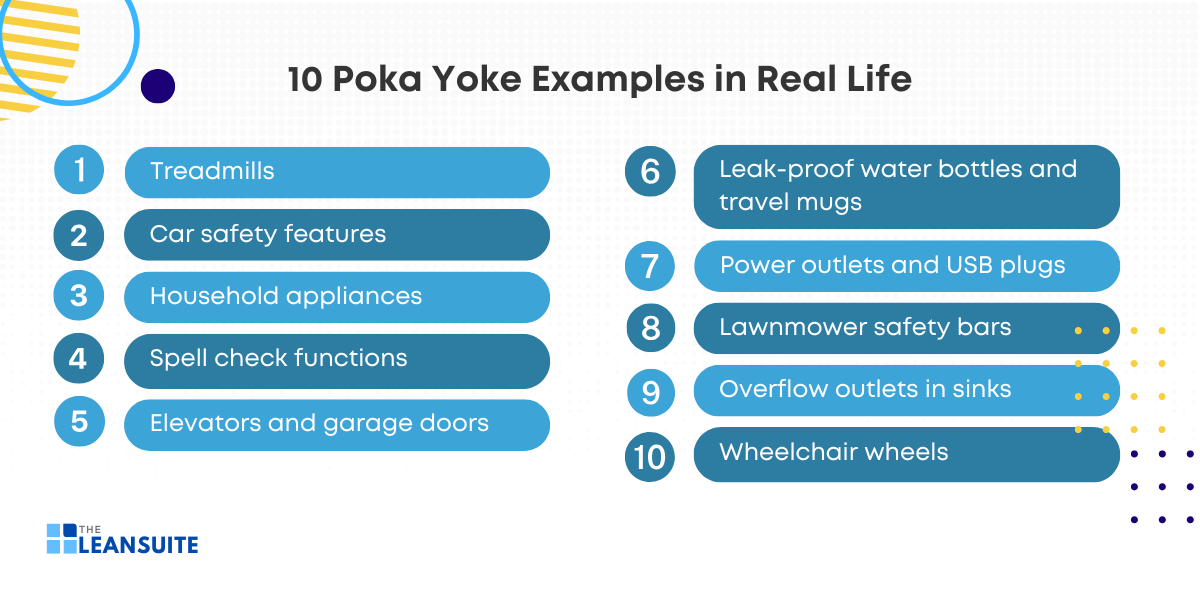

10 Poka Yoke examples in real life

Poka Yoke principles can transform everyday products and processes, making them safer and more efficient. In this section, we will explore ten Poka Yoke examples where its principles are effectively applied. From fitness equipment to household appliances, these examples highlight how thoughtful design can effectively prevent errors and enhance user experience. Moreover, each instance showcases how intuitive design can make complex processes foolproof. Therefore, ensuring safety and efficiency are at the forefront of our daily interactions.

1. Treadmills

Treadmills are designed with user safety as a top priority. One of the most effective ways they achieve this is through the incorporation of a safety key. This key must be securely attached to the user before the treadmill can operate. Essentially, it acts as a critical Poka Yoke device. In the event of a fall or if the user moves too far away from the control panel, the treadmill will immediately stop. Thereby, minimizing the risk of injury.

This simple, yet effective mechanism ensures that users can engage in their workout routines with peace of mind. In other words, it helps them know that the treadmill is equipped to respond quickly to any unforeseen circumstances.

2. Car safety features

The world of modern automobiles is a prime example of how Poka Yoke systems are utilized to enhance driving safety. An abundance of features are designed to alert drivers to potential hazards or unsafe behaviours while on the road and to prevent accidents. For example, seatbelt reminders, automatic braking systems, and lane departure warnings.

These safety mechanisms work together, significantly reducing the likelihood of human error, which is a major contributor to road accidents. For instance, when a driver fails to buckle their seatbelt, an audible reminder prompts them to do so. Furthermore, automatic braking systems can detect imminent collisions and engage the brakes without driver intervention.

3. Household appliances

Household appliances have increasingly adopted Poka Yoke principles to promote safe and effective usage among consumers.

For example, microwaves are engineered to prevent operation unless the door is securely closed. This design choice mitigates the risk of exposure to microwave radiation and ensures that food is cooked properly. Similarly, washing machines are equipped with door locks that engage during operation. Thus, preventing accidental openings that could lead to spills or injuries. Dishwashers often have similar mechanisms, ensuring that users cannot inadvertently open the appliance while it is in use.

These thoughtful design elements highlight the importance of safety in everyday tasks. As a result, this allows people to confidently use their appliances without the fear of mishaps or accidents.

4. Spell check functions

In today’s digital era, the widespread availability of spell check functions can be seen as an essential Poka Yoke tool. This is because it helps users avoid typographical and grammatical errors.

These digital assistants automatically scan text for spelling and grammatical mistakes, highlighting them for users before they finalize their documents. What’s more, the proactive nature of spell checkers enhances the quality of written communication and serves as a valuable learning tool. In fact, it helps users improve their language skills over time.

In professional settings, where clarity and professionalism are important, the use of spell check functions can greatly enhance the quality of written communication. By prompting users to correct errors, spell check functions help prevent miscommunication. Therefore, ensuring that messages are conveyed accurately and effectively.

5. Elevators and garage doors

Safety is a critical concern for the design of elevators and automatic garage doors. For that reason, both commonly incorporate sophisticated safety sensors.

These sensors are engineered to detect any obstructions in the path of the door or elevator. Moreover, it automatically halts their operation to prevent potential collisions or entrapments. For example, if an object or a person stands in the way of a closing garage door, the sensor will trigger a reversal, allowing the door to open instead. This feature not only protects individuals from injury, but also safeguards property from damage.

6. Leak-proof water bottles and travel mugs

The design of leak-proof water bottles and travel mugs showcases Poka Yoke principles by emphasizing user safety and convenience. These products often feature innovative locking mechanisms or specialized seals that prevent spills, even when the container is tipped over.

These design strategies are particularly beneficial for individuals who lead active lifestyles. It allows them to carry liquids without the worry of accidental leaks that can lead to messes or damage to belongings.

The ability to confidently transport beverages in various settings—whether during a commute, at the gym, or while traveling—enhances the user experience significantly.

7. Power outlets and USB plugs

Poka Yoke principles are also evident in the design of power outlets and USB plugs. Both of which incorporate unique shapes and sizes to prevent incorrect connections.

For example, USB plugs are designed to fit only one way. Thereby, eliminating the possibility of forcing a connection that could lead to damage. Similarly, grounded power plugs have specific orientations that ensure they can only be inserted into compatible outlets.

These thoughtful design choices significantly reduce the risk of electrical damage, short circuits, or even electrical fires. These all can occur when users attempt to connect devices improperly.

8. Lawnmower safety bars

Safety is a top priority in lawnmower design. That’s why lawnmowers typically includes a safety bar that must be pressed down to enable the machine to function. This design element serves as a crucial Poka Yoke feature. It ensures that the mower only runs when the operator maintains control. If the user releases the safety bar—whether due to distraction or an accidental slip—the lawnmower’s engine stops immediately. Therefore, preventing unintended activation that could lead to serious injuries.

9. Overflow outlets in sinks

Overflow outlets in sinks are a practical application of Poka Yoke principles. Their primary function is to stop water from overflowing the edges. In other words, these outlets allow excess water to be redirected into the drain. This effectively prevents potential flooding and water damage in homes.

By integrating this simple, yet effective feature, sink manufacturers address a common household problem that can arise when users accidentally leave the tap running or forget to turn it off. The presence of overflow outlets provides an additional layer of safety and convenience. That is to say, it allows users to manage their water usage without the constant fear of spills.

This intuitive design not only enhances the functionality of sinks but also promotes a sense of responsibility among users. In essence, it encourages them to be mindful of water conservation and household maintenance.

10. Wheelchair wheels

Wheelchairs are equipped with anti-tip wheels that play a key role in ensuring user safety. These small wheels, strategically positioned at the rear of the wheelchair, serve as a crucial safety feature that prevents the chair from tipping over backward.

This design consideration is especially important for users with mobility challenges. In fact, it enhances stability and confidence while in motion. By incorporating anti-tip wheels, manufacturers provide individuals with greater independence and security. Thus, allowing them to navigate their environments with less risk of accidents.

Conclusion

In conclusion, Poka Yoke, a Japanese term meaning “mistake-proofing” or “error-proofing,” plays an important role in enhancing safety and efficiency in both industrial settings and daily life. By integrating mechanisms or devices designed to help operators avoid mistakes, Poka Yoke principles ensure that processes and products are intuitive and reliable.

As demonstrated by the ten Poka Yoke examples discussed, it can be applied across various industries and everyday scenarios. This approach prevents errors, boosts productivity, and fosters a more organized and secure environment. Embracing Poka Yoke principles enables both individuals and organizations to reduce human error and enhance their operational efficiency. Ultimately, leading to greater success and peace of mind.