Digital forms are becoming more widely adopted by organizations. This is because the ability to collect and analyze data effectively has become increasingly important to businesses. Companies gather, examine, process and build reports on large volumes of data. So, they need an easier and faster way to manage these processes. In today’s blog, we get into the benefits of using digital forms in manufacturing.

What are the Benefits of Using Digital Forms in Manufacturing?

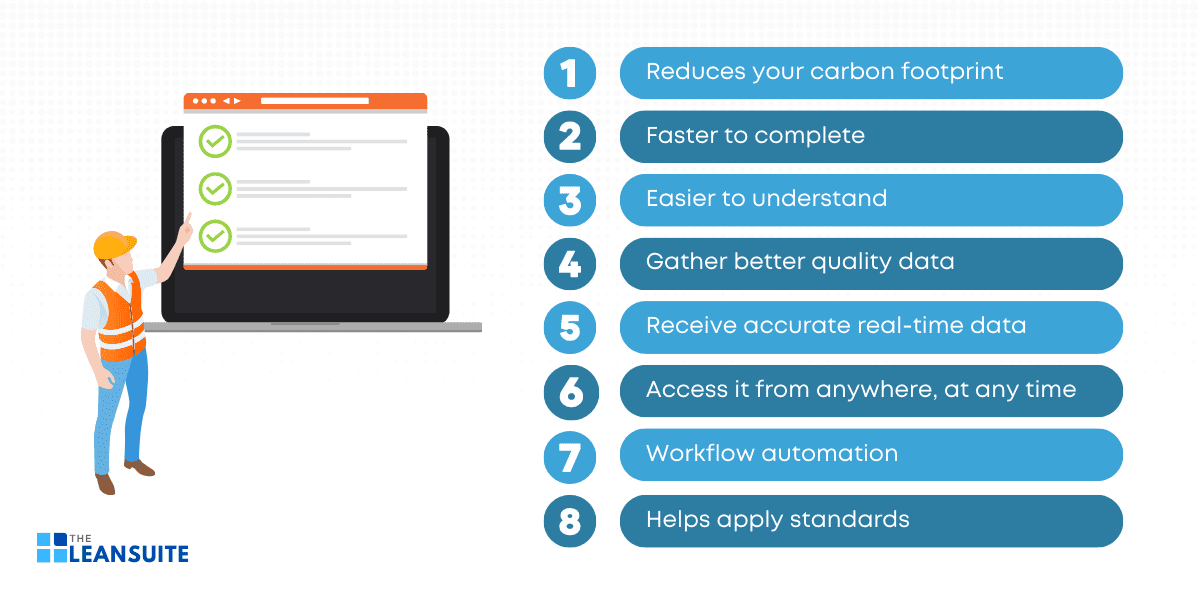

Forms are a fundamental part of many businesses. For manufacturing specifically, they drive all processes and span multiple departments. For instance, they collect information for work order requests and quality control inspections, handle customer purchase requests, and manage time off requests. Many manufacturing businesses are digitally transforming their operations. In other words, they are embracing digital tools and techniques to make it easier and faster to collect accurate data. Here are eight benefits of using digital forms in manufacturing:

1. Reduces your carbon footprint

One of the most obvious benefits of using digital forms in manufacturing is the fact that it reduces an organization’s carbon footprint. Digital forms are an absolute requirement for any paperless factory. What’s more, going paperless offers numerous benefits for minimizing the costs of your back-office processes. Using digital forms eliminates the need to print, store and manage thousands of paper records in file cabinets and storage facilities. As a result, this can have a significant impact on a manufacturer’s bottom line and the environment. For example, you’ll spend less on materials like ink and paper and you’ll be saved from the frustration and cost of searching for and recreating lost forms.

2. Faster to complete

It is no surprise that digital forms are often faster and easier to complete than paper forms. That is to say, for some people, filling out a paper form neatly and legibly can be a big challenge. This is especially true if the form fields in which they are supposed to enter information in are small. What’s more, even if they make a mistake while filling out a digital form, they don’t have to cross it out. Instead, they can just click delete and go back and fix it before submitting the form.

3. Easier to understand

One of the most effective benefits of using digital forms in manufacturing is the ease of understanding it. This is because, digital forms enable additional information, such as images and videos, to be included in the documents. For example, workers can attach photos or videos to digital standard work forms to clearly explain how others should clean, lubricate, and inspect a piece of equipment. Similarly, workers can attach a photo or video while completing a work request form to specifically highlight the area in which they are encountering a problem with their equipment. Therefore, this reduces the need for unnecessary back-and-forth conversations before corrective action can be taken.

4. Gather better quality data

Digital forms can be designed to dramatically reduce data errors and gaps in documents. For instance, if someone attempts to enter text into a field that requires a number, online forms can be triggered to pop up a flag indicating that the data should be re-entered in the proper format. Likewise, you can opt for pick-lists and multiple choice fields to prompt your workers to select from standardized responses. Additionally, you can make some, or all, fields mandatory so that this ensures workers cannot submit the form until all information has been provided.

5. Receive accurate real-time data

By using digital forms, data is instantly digitized and available in real-time. As a result, this increases visibility. This is because there’s no need to wait until the end of day or week for the data to be re-keyed into a central system. Such insightful information can enable your business to generate reports that will be proactive rather than reactive and improve your operations at a faster pace. Digital forms also gives you the ability to provide instant feedback. For example, if a worker submits a suggestion for an improvement opportunity, you can immediately approve it or reject it with some feedback.

6. Access it from anywhere, at any time

The ability to access digital forms from anywhere, at any time is another one of the major benefits of using digital forms in manufacturing. Ever looked for data or that one paper form maybe on the road with no access to your office, and been unable to complete the task? Digital forms can resolve this remote access issue. When your forms are cloud-based, you can easily access them regardless of where you are or what time it is as long as you have internet connection.

7. Workflow automation

Workflow automation might be seen as one of the biggest benefits of using digital forms in manufacturing. After all, it is what enables an organization to streamline its business processes, increase efficiency, and produce higher-quality work. Digital forms allow for automated notifications of workflow assignments to ensure faster, more efficient processing across every department. In other words, real-time workflow integration streamlines the entire document management process. It ensures that forms are getting to the right people, no matter where they are.

8. Helps apply standards

Lastly, one of the key benefits of using digital forms in manufacturing is that it helps share and apply standards across global operations. Corporate stakeholders in safety, quality, and operations can build a library of form templates to quickly and easily share across all plants and factories. This ensures that, for example, a Gemba Walk checklist or a 5S Audit Checklist, is consistent across global operations, making it easier to analyze the data and identify trends.