In the world of business and project management, the concepts of continuous improvement and process improvement are often used interchangeably. However, there are subtle, yet significant, differences between the two concepts that can greatly impact the success of an organization. Understanding these distinctions is crucial for implementing effective strategies to achieve dramatic improvements that drive growth and innovation. In this blog post, we’ll get into the nuances of continuous improvement vs process improvement, exploring how each approach contributes to enhancing operational efficiency and achieving long-term success.

What is continuous improvement?

Continuous improvement is a lean manufacturing technique that focuses on making small, incremental changes to existing processes, products, or services to enhance efficiency, quality, and customer satisfaction. It involves continuously seeking ways to improve operations and eliminate waste by empowering employees to identify problems, propose solutions, and implement changes. By fostering a culture of continuous improvement, organizations can adapt to changing market conditions, stay competitive, and drive innovation.

The Toyota Production System (TPS) is a prime example of how continuous improvement can be implemented successfully. Developed by Toyota, TPS is a manufacturing methodology that aims to maximize efficiency and minimize waste in production processes. Central to TPS is the concept of “kaizen,” which means continuous improvement in Japanese. Toyota empowers its employees to identify inefficiencies, suggest improvements, and implement changes on the production line. This approach has helped Toyota become a leader in the automotive industry by reducing costs, improving quality, and increasing productivity through small, incremental changes made on a daily basis.

What is process improvement?

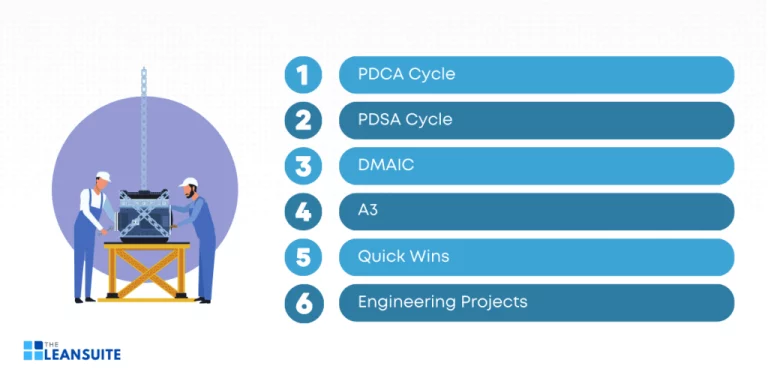

Process improvement is a structured approach to enhancing the efficiency, effectiveness, and quality of processes within an organization. It involves analyzing existing business processes, identifying areas for improvement, and implementing changes to achieve desired results. By focusing on eliminating waste, reducing errors, and streamlining operations, process improvement aims to optimize workflow and enhance overall performance.

There are various methodologies and tools that organizations can utilize to drive process improvement initiatives, such as Six Sigma, Lean Management, and Total Quality Management. These methodologies provide frameworks for identifying root causes of issues, setting goals for improvement, and monitoring progress towards achieving desired outcomes. Continuous improvement is a key aspect of process improvement, as it involves regularly reviewing and refining processes to adapt to changing circumstances and ensure ongoing success. By embracing a culture of continuous improvement, organizations can drive innovation, increase productivity, and deliver greater value to customers.

Key differences between continuous improvement vs process improvement

Continuous improvement and process improvement are both concepts used to enhance organizational processes. However, they differ in their approach and scope. There are three key differences that distinguish continuous improvement and process improvement from each other.

Small changes over time vs large changes over time

Continuous improvement focuses on making small, incremental changes over time to enhance efficiency, quality, and effectiveness. These changes are often made by frontline employees who are closest to the processes and can identify areas for improvement on a day-to-day basis. On the other hand, process improvement involves making larger, more significant changes to a specific process or system in order to achieve a specific goal or address a major issue. In short, while continuous improvement is about ongoing refinement and optimization, process improvement is more about strategic redesign and transformation.

Systematic approach vs goal-oriented approach

Continuous improvement takes a systematic approach to change and doesn’t have specific endpoint goals or timelines. It emphasizes the constant evaluation of existing processes to identify areas for enhancement in all aspects of an organization, not just in isolated processes. On the other hand, the process improvement methodology is more goal-oriented. It concentrates on achieving specific targets or outcomes within a set timeframe. In other words, it often involves setting clear objectives, such as reducing defects or lead times, and implementing changes to achieve those goals. Essentially, while continuous improvement aims to create a culture of constant evolution and refinement, process improvement is often driven by specific objectives or milestones.

Long-term focus vs short-term focus

Continuous improvement typically focuses on long-term goals and strategies for sustainable growth and development. It involves a continuous cycle of identifying areas for enhancement, implementing changes, and evaluating outcomes to drive ongoing progress. On the other hand, process improvement tends to have a more short-term focus. It seeks immediate gains from addressing specific issues or inefficiencies within a particular business process or workflow. What’s more, process improvement often utilizes SMART goals – Specific, Measurable, Achievable, Relevant, and Time-bound – to achieve tangible and immediate results within a defined timeframe. In sum, while continuous improvement fosters a culture of ongoing learning and adaptation, process improvement is more targeted towards quick wins and immediate impact on operational processes.

Continuous improvement benefits and limitations

While continuous improvement is a powerful strategy for improving business processes, it can come with its own set of challenges and constraints that are important to consider.

Benefits of continuous improvement

1. Increases efficiency and productivity

By continuously analyzing processes and making incremental changes, organizations can streamline workflows, reduce waste, and ultimately achieve higher levels of efficiency. This can lead to dramatic improvements such as cost savings, improved quality, and faster delivery of products or services.

2. Enhances employee engagement and satisfaction

When employees are encouraged to participate in identifying areas for improvement and implementing solutions, they feel empowered and valued. This can boost morale, motivation, and overall job satisfaction. Engaged employees are more likely to contribute ideas, collaborate effectively, and take ownership of their work, leading to a more positive and productive work environment.

3. Fosters innovation and adaptability

By constantly seeking ways to enhance current processes and stay ahead of the competition, organizations can adapt to changing market conditions and customer needs more effectively. This proactive approach encourages a culture of innovation, creativity, and learning within the organization, enabling it to thrive in a rapidly evolving business landscape.

Limitations of continuous improvement

1. Resource constraints

Implementing continuous improvement requires dedicated resources, such as time, money, and personnel. Organizations may struggle with allocating these resources, especially in the face of competing priorities or tight budgets. In essence, limited resources can hinder the ability to sustain long-term continuous improvement efforts.

2. Resistance to change

Change can be challenging for employees. This can be especially true if they have been accustomed to a certain way of working for a long time. Resistance to change can impede the success of continuous improvement initiatives. This is because employees may be reluctant to embrace new processes or technologies. As a result, this can lead to a lack of buy-in and collaboration.

3. Diminishing returns

While continuous improvement of existing systems can lead to significant enhancements initially, over time, the law of diminishing returns may come into play. As processes become more refined, the incremental benefits of further improvements may decrease. This makes it harder to justify the ongoing effort and resources required for additional optimizations.

Process improvement benefits and limitations

Like continuous improvement, while process improvement is a powerful strategy that can revolutionize businesses, there are some challenges and constraints that are important to consider.

Benefits of process improvement

1. Increases efficiency

By analyzing and optimizing workflows, businesses can eliminate unnecessary steps, reduce bottlenecks, and ultimately save time and resources. This increased efficiency can lead to higher productivity levels and improved overall performance.

2. Streamlines processes

Through the identification of bottlenecks and areas of inefficiency, organizations can streamline and optimize their existing processes. Streamlining processes not only further increases efficiency, but also helps in creating a more structured and organized work environment.

3. Helps control critical issues

By identifying and addressing areas of weakness or inefficiency, businesses can proactively tackle problems before they escalate. This proactive approach can help prevent costly mistakes, improve decision-making processes, and foster a culture of continual improvement from within the organization.

Limitations of process improvement

1. Risk of over-engineering

Striving for process perfection may lead to the danger of over-engineering. This occurs when processes are overly complicated or sophisticated, leading to inefficiencies and unnecessary costs. Therefore, it’s important to strike a balance between streamlining processes and ensuring they remain practical and effective.

2. Unforeseen consequences

The implementation of process reengineering on any existing system may have ripple effects on other areas. As a result, this may cause disruptions or issues that were not initially foreseen. That’s why it’s important to conduct thorough impact assessments and involve stakeholders from across the organization in the process improvement efforts.

3. Lack of alignment

If process improvements are not closely tied to the broader objectives of the organization, they may not deliver the intended outcomes or drive the desired results. That is to say, it’s essential for process improvement initiatives to be guided by a clear understanding of the organization’s vision, mission, and strategic priorities to ensure they contribute meaningfully to its success.

Continuous improvement vs process improvement: which should you pick?

When deciding between continuous improvement vs process improvement, it’s essential to consider the specific business needs and goals of your organization. However, many organizations often opt for a hybrid approach that combines elements of both concepts. This allows them to benefit from the ongoing enhancements associated with continuous improvement, while also addressing larger systemic issues by applying process improvement methodologies and techniques when appropriate. By blending these approaches, organizations can create a balanced strategy that enhances existing processes and drives business strategy. Ultimately, the key is to tailor the approach to the unique needs and circumstances of the organization to achieve the best possible results.