Achieving operational excellence in manufacturing requires more than just efficient processes and state-of-the-art machinery. That is to say, it requires a holistic approach to continuous improvement, effective loss management, and strategic cost deployment. LeanSuite is your comprehensive solution designed to elevate your Lean manufacturing initiatives, especially within the Obeya room environment. In this blog, we will explore what an Obeya room is, its principles, and how LeanSuite can enhance Obeya room activities, driving your organization towards greater efficiency and success.

What is an Obeya room?

https://www.youtube.com/watch?v=MGlno1aI7rk

An Obeya room is a Japanese word for “big room” and is also often referred to as a “war room”. Essentially, it is a collaborative space used primarily in Lean management and project management practices.

Originating from Toyota’s production system during World War II, Obeya rooms were designed to enhance communication, transparency, and problem-solving among team members. These strategic spaces have since become essential elements of Lean and Agile methodologies.

Within this dedicated space, teams can visualize project progress, organize key information visually, address issues in real-time, make data-driven decisions by having all relevant information and stakeholders in one place, and foster team collaboration to enhance communication and expedite problem resolution.

An Obeya room typically features large visual boards, charts, and other visual management tools, that aid in tracking performance metrics, timelines, and tasks. Ultimately, an Obeya room fosters a culture of continuous improvement and efficient collaboration, driving projects forward more effectively.

How Lean, Agile, and Obeya are historically linked

Lean management, Agile methodologies, and Obeya are three key concepts in modern organizational efficiency. Moreover, these methodologies significantly improve the project management process by enhancing collaboration and communication through the Obeya/Big Room approach.

The historical linkage among these practices lies in their shared goal of maximizing value while minimizing waste, fostering continuous improvement, and enhancing team collaboration.

Lean management

Lean management, also known as Lean process management, originated from the Toyota Production System (TPS) in Japan during the 1950s.

Pioneered by Taiichi Ohno and Eiji Toyoda, the TPS was revolutionary in its approach to manufacturing. It emphasized the elimination of waste (muda), continuous improvement (Kaizen), and respect for people. These principles aimed to create more value for customers with fewer resources.

Over time, the core principles of Lean management expanded beyond manufacturing and were adapted into various industries. Thus, forming the backbone of many organizational efficiency strategies today.

Agile methodologies

Agile methodologies, which emerged in the early 2000s, particularly within the software development industry, share many principles with Lean management.

This methodology emphasizes flexibility, iterative progress, and customer collaboration. The Agile Manifesto was created by a group of software developers and it outlines values and principles that prioritize:

- Individuals and interactions over processes and tools

- Working software over comprehensive documentation

- Customer collaboration over contract negotiation, and

- Responding to change over following a plan

Agile methodologies like Scrum and Kanban borrow heavily from Lean principles. In fact, it focuses on continuous improvement, efficiency, and delivering value incrementally.

Today, this historical linkage extends into Agile manufacturing, which applies Agile principles to the production floor. In other words, it enables manufacturers to swiftly adapt to market changes, reduce lead times, and enhance product quality through cross-functional teams and flexible processes.

Obeya

Obeya is a practice that integrates the principles of Lean and Agile by fostering a collaborative environment.

The Obeya concept involves creating a dedicated physical space where cross-functional teams can come together to discuss, plan, and solve problems in real-time using visual management tools. This physical embodiment of Lean communication and Agile collaboration promotes transparency, alignment, and rapid decision-making.

By bringing together project teams made up of diverse perspectives and expertise, Obeya facilitates a holistic approach to project management and process improvement. Therefore, ensuring that all team members are aligned with your organization’s goals and objectives.

Summary

In summary, Lean management, Agile methodologies, and Obeya are historically linked through their shared focus on efficiency, collaboration, and continuous improvement.

While Lean management laid the foundational principles, Agile methodologies adapted these concepts to the ever-changing demands of software development, and Obeya provided a practical framework for fostering real-time collaboration.

Together, these practices complement each other, resulting in enhanced customer satisfaction, quicker innovation cycles, increased employee morale, and overall improved organizational performance.

The principles of Obeya

The four Obeya quadrants

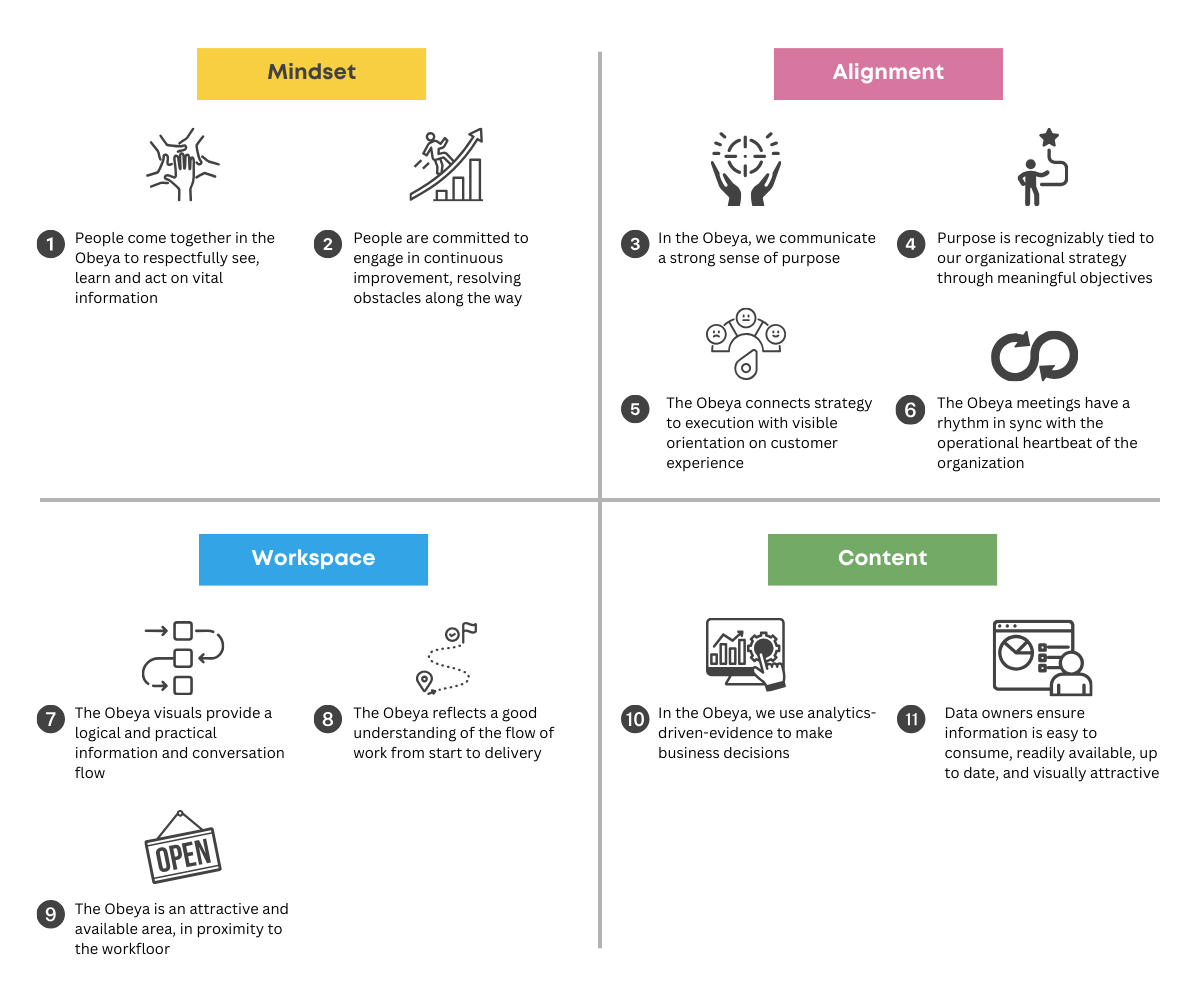

An Obeya is as much about creating an effective workspace environment as it is about fostering effective behaviour. Hence, the both are organized into four essential quadrants that lay the groundwork for creating a successful Obeya that promotes collaboration, alignment, and continuous improvement:

- Mindset: The Mindset quadrant focuses on cultivating a collaborative and growth-oriented mindset within the Obeya

- Alignment: Alignment ensures that the purpose of the Obeya is aligned with the broader organizational strategy

- Workspace: Workspace emphasizes the physical, digital, and virtual design and setup of the Obeya to ensure that there is effective communication, collaboration, and engagement

- Content: Content represents the quality and relevance of the information and data shared within the Obeya that drive and support informed decision-making

The 11 Obeya principles

The 11 Obeya principles are meant to guide Obeya use and development. They are:

- People come together in the Obeya to respectfully see, learn and act on vital information

- People are committed to engage in continuous improvement, resolving obstacles along the way

- In the Obeya, we communicate a strong sense of purpose

- Purpose is recognizably tied to our organizational strategy through meaningful objectives

- The Obeya connects strategy to execution with visible orientation on customer experience

- The Obeya meetings have a rhythm in sync with the operational heartbeat of the organization

- The Obeya visuals provide a logical and practical information and conversation flow

- The Obeya reflects a good understanding of the flow of work from start to delivery

- The Obeya is an attractive and available area, in proximity to the workfloor

- In the Obeya, we use analytics-driven-evidence to make business decisions

- Data owners ensure information is easy to consume, readily available, up to date, and visually attractive

The Obeya principles framework

These 11 principles further define how to approach work in an Obeya in every quadrant.

How LeanSuite integrates with Obeya room activities

1. Robust Kaizen implementation

Obeya is a central hub for project management and continuous improvement. By leveraging LeanSuite, you can implement and track Kaizen initiatives seamlessly within your Obeya room through:

- Idea management: Team members can easily capture and prioritize improvement ideas during Obeya meetings, ensuring that no valuable suggestion is overlooked.

- Action tracking: Monitor Kaizen activities in real-time with visual dashboards, keeping your team informed and aligned on the progress of their initiatives.

- Impact analysis: Evaluate the effectiveness of these initiatives by tracking key performance indicators (KPIs) and cost savings, ensuring that each Kaizen effort is contributing positively to your organization’s goals.

2. Comprehensive loss management

Effective loss management is essential for identifying and eliminating waste in your manufacturing processes, helping you to maintain optimal productivity and efficiency. LeanSuite offers advanced features to support these efforts, including:

- Loss tree analysis: Utilize visual loss trees to pinpoint the root causes of inefficiencies and their resultant impacts.

- Real-time monitoring: Integrate with sensors and IoT devices to gather real-time data on equipment performance and process efficiency, enabling quick identification of issues and prompt responses.

- Corrective actions: Develop and implement corrective action plans directly within the Obeya room, ensuring that all stakeholders are aligned and informed. Thereby, fostering a collaborative approach to problem-solving and continuous improvement.

3. Strategic cost deployment

LeanSuite integrates seamlessly with Obeya room activities by streamlining strategic cost deployment. That is to say, it ensures that resources and efforts are precisely aligned with organizational goals to maximize value creation through:

- Cost allocation: Accurately assign costs to specific projects and processes, offering a transparent view of resource utilization. This clarity enables teams to identify inefficiencies and redirect efforts where they are most needed.

- Budget tracking: Monitor adherence to budgets and pinpoint opportunities for cost reduction during Obeya meetings. This continuous oversight ensures that financial resources are used effectively and that any deviations from the budget are promptly addressed.

- Financial impact assessment: Evaluate the financial impact of your Lean initiatives and make data-driven insights that enable you to evaluate the outcomes of your cost deployment strategies.

Why you should enhance Obeya room activities with LeanSuite

LeanSuite, a comprehensive Lean enablement software, is an invaluable tool in the Obeya room—a central space for team collaboration in Lean organizations. Here are four reasons why you should enhance Obeya room activities with LeanSuite:

1. Enhanced collaboration

One of numerous benefits of using LeanSuite in the Obeya room is that it significantly enhances collaboration.

LeanSuite fosters cross-functional collaboration by offering a unified platform where all team members can contribute, track, and discuss their ideas and progress in real-time. As a result, this integrated approach ensures that everyone, regardless of their department or role, has a voice in the decision-making process.

By providing a centralized location for sharing insights and updates, LeanSuite helps maintain transparency and encourages open communication. This collaborative environment is crucial for the success of Obeya room activities and for achieving project success, as it ensures that all perspectives are considered. Hence, leading to improved communication, more cohesive decision-making, and a unified approach to problem-solving.

2. Improved transparency

Using LeanSuite in the Obeya room significantly improves transparency by leveraging its advanced visual management tools.

With LeanSuite’s charts, graphs, and dashboards, the status of projects and initiatives is always clearly visible to all team members. This constant visibility, in turn, allows teams to quickly identify any issues, track the progress of various tasks, and make informed decisions during Obeya meetings.

The visual representations provided by LeanSuite ensures that everyone in the project team is on the same page. Therefore, promoting a collaborative environment where misunderstandings are reduced, problems are addressed promptly, and solutions are devised efficiently.

3. Increased efficiency

An important advantage of using LeanSuite in the Obeya room is the significant boost in efficiency achieved by combining Kaizen, loss management, and cost deployment into one unified platform.

This efficient method combines essential processes, reducing the time and effort spent on administrative tasks. By eliminating the need to switch between multiple tools or manually compile data, LeanSuite allows your teams to focus their energy on value-added activities and continuous improvement efforts.

Consequently, this heightened efficiency not only accelerates decision-making, but also fosters a culture of ongoing enhancement and innovation. Ultimately, LeanSuite not only makes it easier to enhance Obeya room activities, but also drives better outcomes for your organization.

4. Real-time insights

LeanSuite offers real-time insights that are invaluable for discussions during your Obeya room meetings.

Its advanced data integration and analysis capabilities ensure that your teams have access to the most current information. In other words, it facilitates proactive problem-solving and more effective decision-making.

By providing real-time data, LeanSuite allows your teams to collaborate effectively to quickly identify and address issues. Thus, maintaining the momentum of continuous improvement. This real-time insight is crucial in the Obeya room, where timely and accurate information supports dynamic discussions and strategic planning.

Conclusion

To sum up, LeanSuite is designed to enhance your Lean manufacturing practices by providing comprehensive solutions for Kaizen, loss management, and cost deployment. By leveraging LeanSuite within your Obeya room, you can drive greater collaboration, transparency, and efficiency. Thereby, leading to improved operational performance and business success.

Enhance Obeya room activities with LeanSuite and experience the power of integrated Lean solutions. Contact us today to learn more and schedule a demo.