In today’s global economy, you need to be able to adjust to changing markets, conditions, and technologies. This is where operational excellence comes in. It’s a great way for organizations to establish continuous improvement in a complex business environment. In today’s blog, we’ll be discussing what the key principles of operational excellence are in addition to what operational excellence is.

What is Operational Excellence?

Operational excellence (OpEx) is a business management approach that applies continuous improvement in every part of a business and within all business processes. This is done by creating a culture where leaders and employees contribute to business outcomes and are empowered to implement change. In other words, it can simply be described as a philosophy that businesses use to embrace problem-solving and leadership as the key to continuous improvement.

Operational excellence starts with a culture shift. All leaders and employees are expected to focus on creating not only quality products, but providing satisfactory customer experiences as well. Businesses that practice operational excellence techniques and methodologies clearly define leadership and workforce roles, and how they work together to improve overall operations. What’s more, employees at any and all levels can initiate change and help drive a business towards efficiency, agility, and effectiveness.

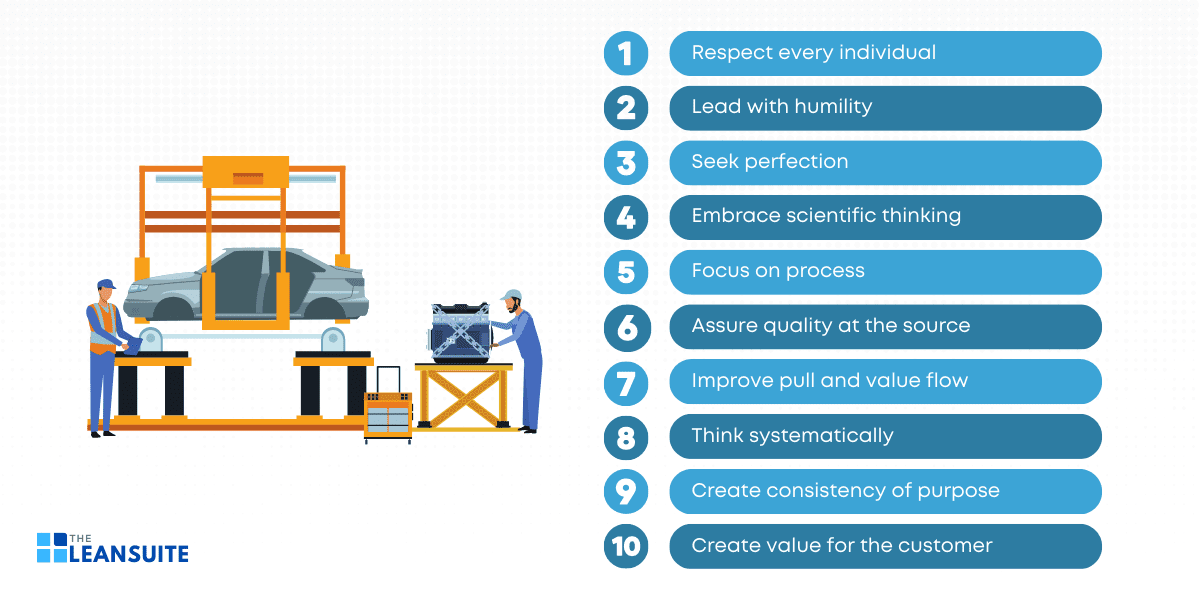

The 10 Key Principles of Operational Excellence

Operational excellence has relational ties to the Shingo Model. It was created by Dr. Shigeo Shingo, a Japanese industrial engineer who was considered as the world’s leading expert on manufacturing practices and the Toyota Production System (TPS). In fact, he closely collaborated with Toyota executives to apply his principles in their manufacturing operations, influenced the creation of Kaizen, and developed the concept of the Single-Minute Exchange of Die (SMED).

Shingo is also the inspiration for the Shingo Prize of Operational Excellence. It is an award for operational excellence given to organizations all around the world by the Shingo Institute. This prize defines the 10 Shingo Guiding Principles, or also known as the key principles of operational excellence:

1. Respect every individual

The very first key principle of operational excellence is to treat everyone with respect. The best way to show respect towards employees is to appreciate their work and skills. It can also be done by getting them to contribute and participate in higher-level business decisions. For example, this can be done by collecting employee feedback and rewarding them for their suggestions. When people feel respected and valued by an organization, they are more likely to perform better and have the organization’s best interests at heart.

2. Lead with humility

The next key principle of operational excellence is to never forget the importance of employees and lead with humility. It’s impossible to lead an organization to success by yourself — you will need the help and support of your employees. Therefore, be open to the idea of self-improvement, ask for employee feedback and input, listen carefully, disregard rigid top-down thinking, and continuously learn. You don’t have to do what others say, but don’t reject their suggestions without giving them a chance to speak.

3. Seek perfection

Seeking perfection is one of the key principles of operational excellence that people might scratch their heads about. This is because we’re often told and taught to not go after perfection and that perfection is impossible. However, the truth is that perfection can be achievable in the business world. Nonetheless, no organization can achieve perfection unless it aims to achieve it. This principle is similar to the saying, “you have to believe it to achieve it.” So, by identifying opportunities to continuously improve, you can unravel new ways of thinking and innovation.

4. Embrace scientific thinking

This fourth key principle of operational excellence isn’t just about being data-driven. Embracing scientific thinking in business means being open to new ideas, allowing ourselves to experiment, and documenting each lesson learned to promote growth. In other words, it’s important to create a culture where employees can experiment and test new ideas based on observations and data. As a result, this fosters innovation.

5. Focus on process

It’s easy to blame people and point fingers at one another when something goes wrong in a process. But most of the time, the root cause is related to the process, not the people. Therefore, the fifth key principle of operational excellence is to focus on the process and look for ways it can be improved. After all, operational excellence is the result of finely tuned processes.

If something goes wrong, the first step should always be to perform an audit. Leaders must focus on the ‘process’ and not the person ‘performing’ it to determine what happened. This is because no matter how good your employees are, they won’t be able to perform well if the process is flawed. However, there are some cases where employees might be at fault. If this is the case, the best way to solve this problem and to achieve operational excellence is to ensure proper training is provided to the employees. Doing so will allow them to play their part in achieving operational excellence and transfer value to the customer.

6. Assure quality at the source

Just like good food is made with good ingredients, you must ensure quality products are made by doing work right the first time, using the right people, and the right components. Nonetheless, if any process produces defective outputs, the root cause must be identified and addressed immediately. Improvement is a continuous process. So, leaders should keep a close eye on all processes and make sure that each process or step adds value to the product or service.

7. Improve pull and flow value

The main goal of every business should be to offer maximum value to its consumers. Hence, the seventh key principle of operational excellence is to improve pull and flow value. That is to say, in order to maximize value for customers, you must create it only in response to demand and to maintain a continuous and uninterrupted flow. When the flow of value is disrupted, this results in inefficiencies and waste. Therefore, leaders must take steps to ensure there are no disturbances and processes are completed in a neat and timely manner.

8. Think systematically

Refrain from focusing on individual team members or departments for improvement. Instead, the eighth key principle of operational excellence suggests that you think of ways to improve the system as a whole. An organization comprises of several departments that must all work together to achieve operational excellence. Thus, leaders must understand the connection between each department and ensure that every department does its job in the best possible way. If you only focus on a single department, you will only end up improving one part of the process but will never produce a good end product.

9. Create consistency of purpose

The ninth principle of operational excellence is to work on creating consistency of purpose. This means all the employees from top-level management to low-level staff members must be on the same page. Everyone in the organization must

- — Understand the mission of the organization

- — The long-term strategic objectives and goals

- — What operational excellence is

- — The individual’s own role in the organization’s success

As a result, this clarity of purpose helps everyone make better decisions, innovate with purpose, and take calculated risks. In sum, an organization needs to be consistent in maintaining the flow of value to establish sustainable growth.

10. Create value for the customer

Ultimately, all businesses are all about the customer. So, the tenth and final key principle of operational excellence is to create value for the customer. This can be done by finding out what they truly want or need. Doing so is important because consumer demands are consistently changing. Additionally, you need to be know what they require and what you can do to meet their expectations.