What is Total Productive Maintenance?

Total Productive Maintenance (TPM) is a strategy that strives to achieve perfect production through the active involvement of all supporting departments. The goal of TPM is to eliminate the following losses:

- — Unplanned downtime

- — Employee error

- — Product defects

- — Employee accidents

- — Wasted resources

- — Labor inefficiencies

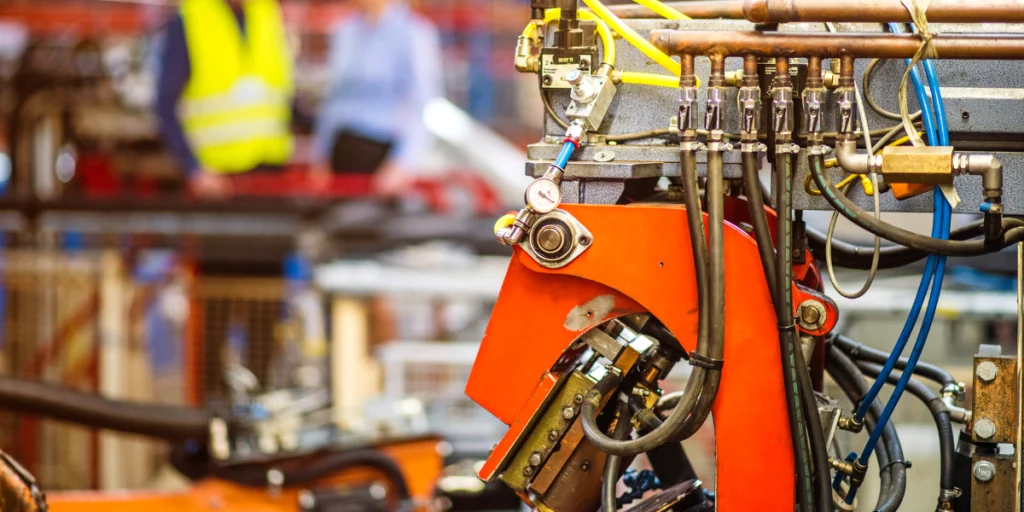

TPM objectives are achieved by implementing preventative maintenance programs, continuously training technicians, and effectively maintaining communication between maintenance and production employees. What’s more, TPM focuses on proactive and preventive maintenance to optimize equipment efficiency and availability. In essence, it places a strong emphasis on empowering production employees to maintain their equipment. This is done through the completion of technical skills training, the evaluation of productivity benchmarks, and following proactive maintenance schedules.

In sum, by implementing a TPM program, this creates a shared responsibility for equipment that encourages greater contribution and involvement from manufacturing plant and factory workers. It is also important to note that organizations who want to implement TPM need to actively involve both maintenance and production employees throughout the TPM process.

The Foundation of TPM

The foundation of total productive maintenance is built on the 5S methodology and is supported by eight pillars. These eight pillars are typically focused on proactive and preventive maintenance techniques for improving machine and equipment reliability.

Three Key Benefits of Total Productive Maintenance

1. Less unplanned maintenance

By carefully planning and scheduling maintenance, the equipment will be well taken care of. Furthermore, TPM empowers all machine operating personnel to champion ownership and take accountability of their machines. In short, TPM makes maintenance personal, and therefore, machines and equipment are better cared for.

2. Reduced equipment downtime

When machine operators proactively watch out for changes with their equipment, big problems can be identified early. As a result, this reduces equipment downtime. Additionally, this enables maintenance teams to easily manage their PM maintenance schedule, instead of always having to react to emergency breakdowns. Essentially, total productive maintenance means more planned maintenance, which results in reduced equipment downtime. That is to say, the more you initiate proactive maintenance activities, the less equipment downtime you’ll have.

3. Improved workplace safety

Since the foundation of total productive maintenance is based on the 5S methodology, the workplace is consistently cleaned and organized. What’s more, when everyone keeps maintenance in mind, problems can be identified and resolved before they become bigger, and possibly dangerous, situations.